Proving thermoplastic composites match carbon fiber/epoxy performance in road bikes

CDCQ, LxSim, Addcomp and Argon 18 collaborate to optimize a carbon fiber/PA6 bike seat post, democratizing AFP and demonstrating materials and process for future designs and production.

Release time:

2024-11-19

Thermoplastic composites (TPC) are at the forefront of the revolution in materials and processes for the cycling industry, says Vincent Lemay, VP of R&D for Argon 18, a high-quality bike manufacturer in Montreal, Canada. “I think the industry will go this way in the near future, because these materials enable quick, efficient and less labor-intensive processes [see CW’s 2022 feature on bike frames]. But in the cycling industry, we have very detailed, tailored layups, which is why they are done manually right now.”

These layups are also almost exclusively thermoset composites, notes Lemay, using carbon fiber-reinforced polymer (CFRP) based on epoxy prepreg for road racing models, where lightweight performance is paramount. “This is what we wanted to address,” he explains. “How can we develop comparable carbon fiber (CF) layups with thermoplastics yet retain the high performance of traditional epoxy-based CFRP?”

BLOG

Latest Blog

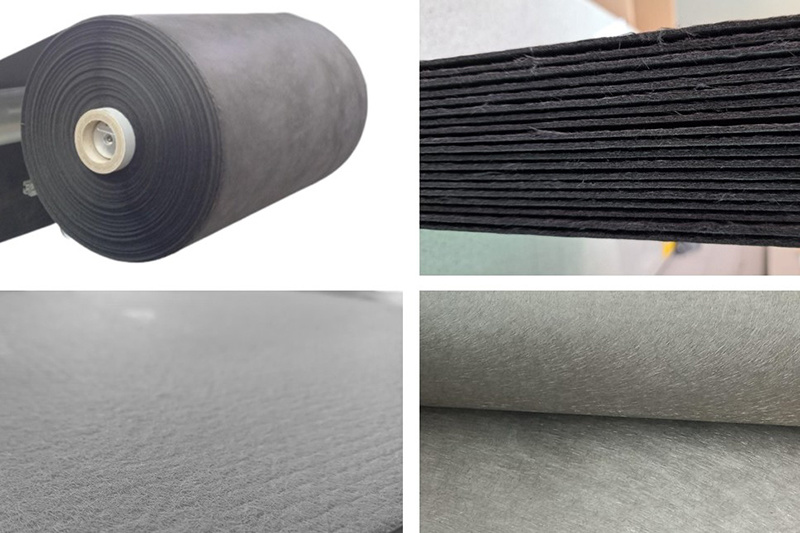

NonWoven365 offers nonwovens, paper solutions portfolio targeting CMC, high-temp applications

Proving thermoplastic composites match carbon fiber/epoxy performance in road bikes

Carbon fiber board performance characteristics