Carbon fiber board performance characteristics

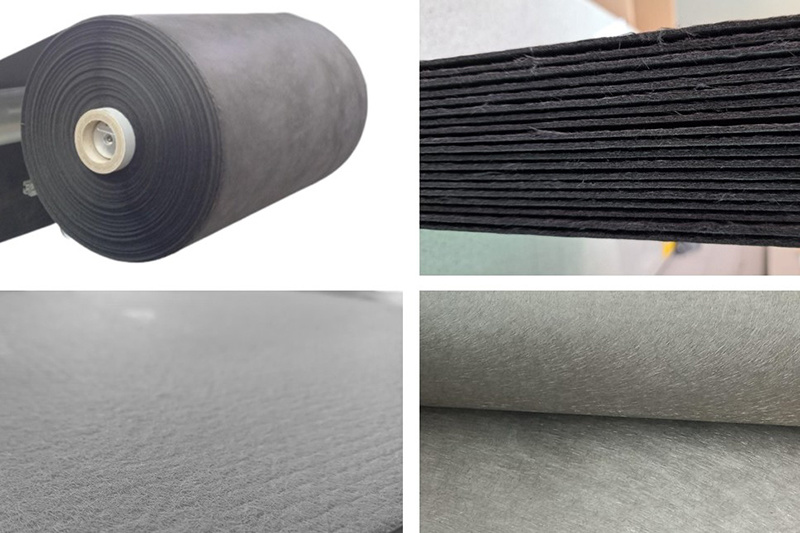

Carbon fiber board is a kind of composite material board made of carbon fiber and resin through a specific process. The following is a detailed description of carbon fiber board:

Release time:

2024-10-24

Carbon fiber board is a kind of composite material board made of carbon fiber and resin through a specific process. The following is a detailed description of carbon fiber board:

Material composition:

Carbon fiber: as the main reinforcing material, it has the characteristics of high strength, high modulus and low density.

Resin: as the matrix material, it bonds the carbon fibers together and gives the sheet shape and dimensional stability.

Production process:

Cutting of prepreg: Cut the carbon fiber prepreg according to the length, width and thickness of the sheet.

Layering of prepreg: According to the demand of tensile force and strength of the sheet, the direction and sequence of laying carbon fiber prepreg are reasonably designed.

Molding and curing: the stacked carbon fiber boards are molded together and put into the press to cure under specific temperature, time and pressure.

Post-processing: including cutting, drilling and other processing to meet the accuracy or assembly requirements.

Performance Characteristics:

High tensile strength: the tensile strength of carbon fiber board is more than several times that of ordinary steel.

Good corrosion resistance: resistant to acid, alkali, salt and atmospheric environment, no need for regular maintenance.

Strong seismic and impact resistance: it has good seismic and impact resistance.

Lightweight: the quality is only 1/5 of steel, which can significantly reduce the weight of the structure.

Good flexibility: It has high toughness and can be coiled for easy construction.

Convenient construction: the material does not need to be pre-processed, the process is convenient, and the plates allow cross.

Application areas:

Civil engineering: used for reinforcement of concrete beams, floor slabs, bridge slabs, etc.

Aerospace: used for the production of drone fuselage, square cabin door plate and other parts.

Medical equipment: used for making medical bed boards to improve the overall performance of medical equipment.

Sports equipment: such as soccer leg guards, paddle boards, etc.

Testing parameters (for reference)

Surface density: 2 kg/m²

Resin content: 42%

Fiber content: 1050 g/m²

Fiber volume content: ≥65%

Thickness: 1.3±0.05 mm

Density: 100±2 mm

Tensile strength: 2950 N/mm².

Carbon fiber board has become one of the indispensable materials in modern industry with its excellent performance and wide range of applications.

BLOG

Latest Blog

NonWoven365 offers nonwovens, paper solutions portfolio targeting CMC, high-temp applications

Proving thermoplastic composites match carbon fiber/epoxy performance in road bikes

Carbon fiber board performance characteristics